Classifications of the robot arm used for injection molding machines

The robot arm used for injection molding machines can be divided into two types: basic injection molding manipulators and intelligent injection molding manipulators.

The basic injection molding manipulator generally includes a fixed mode program and a teaching mode program according to the requirements of the production process. The fixed mode program covers several standard processes of injection molding production, using industrial controllers to do simple, regular and repetitive actions. The teaching mode program is specially adapted for injection molding machines with special production processes, and achieves the purpose of successfully taking goods by orderly and safe arrangement of basic movements.

The intelligent injection molding manipulator generally has functions such as multi-point memory placement, being on stand by at any point and more degrees of freedom. Servo-driven is generally adopted, which can perform more complex operation with the maximum imitation of humans. The intelligent injection molding manipulator can be equipped with advanced sensors to make it have visual, tactile and thermal functions, and become a highly intelligent injection robot.

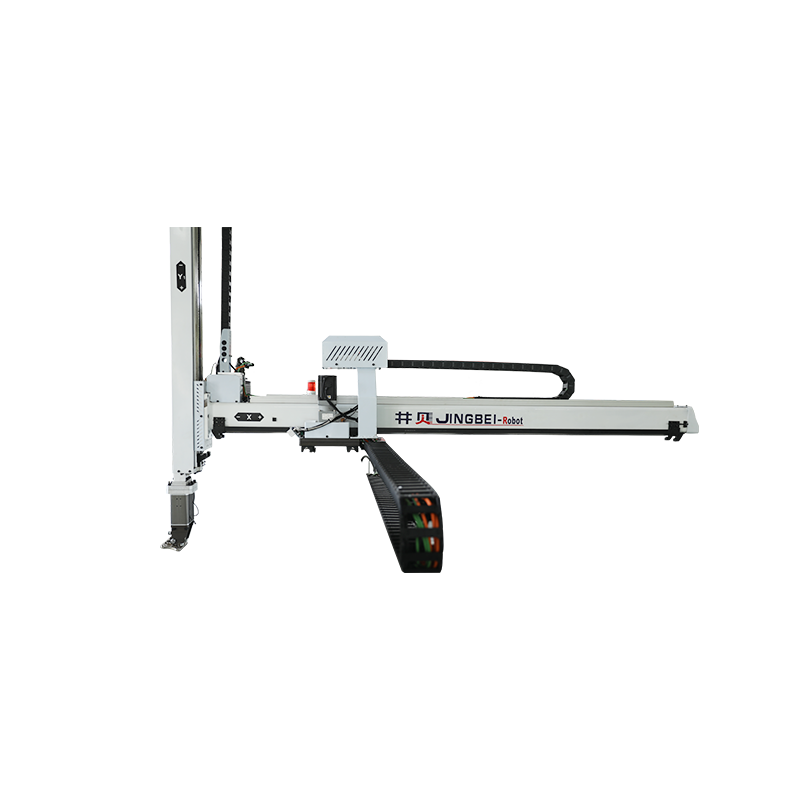

The structure of the manipulator for injection molding machines

(1) Execution systems

1. Hands

The hand is mounted on the front end of the arm. The inner hole of the arm is equipped with a transmission shaft, which can turn or stretch the wrist, open or close the fingers. The structure of the manipulator's hand imitates human fingers, and it is classified into three kinds: fingers with no joints, fingers with fixed joints and free joints. There are robot arms with two fingers, three fingers and four fingers, among which two fingers are used most. According to the shape and size of the clamping object, various shapes and sizes of clamping heads should be equipped. The so-called hands without fingers generally refer to vacuum or magnetic suction chucks.

2. Arms

The function of the arm is to guide the fingers to grasp the workpiece accurately and send it to the desired position. In order for the manipulator to work correctly, the 3 degrees of freedom of the arm must be accurately positioned.

3. Bodies

The body is a bracket for installing arms, power sources and various actuators.