With the rapid development of Intelligent Industry 4.0, our traditional injection molding industry manipulators have also used manipulators instead of manual for automatic nozzles, in-mold inserts, in-mold labeling, out-of-mold assembly, shaping, classification, stacking, product packaging, Mold optimization and so on. The special servo manipulator for injection molding machine is an automatic production equipment that can imitate part of the functions of the upper limbs of the human body and can automatically control it to transport products or operate tools for production operations according to predetermined requirements. Servo manipulator is a machine specially equipped for injection molding production automation. It can reduce heavy physical labor, improve working conditions and safe production; improve the production efficiency of injection molding machines, stabilize product quality, reduce scrap rates, reduce production costs, and enhance enterprises Competitiveness and other aspects play an extremely important role. What are its usage methods and precautions in use? Below we give you an overview as follows:

1. How to use the manipulator of the injection molding machine

1. Confirm that the power source, air pressure source and other power sources are properly connected, and check the pressure of the manipulator air pressure regulator to 0.4mpa-0.6mpa.

2. Turn on the power of the manipulator and perform the manipulator origin return action.

3. Set each action mode of the manipulator (select according to the needs of the specific product).

4. According to the labeling parameters on the manipulator fixture, enter the manipulator standby position and gripping position.

5. Set the mold opening stroke of the injection molding machine according to the parameters on the label.

6. Inspect whether the clamp screws are loose, whether the holding clamp clip is damaged, whether the cylinder expansion and contraction is normal, whether the air leaks, whether the suction cup is intact, whether the fittings are stuck and other bad phenomena.

7. After the fixture is installed OK, observe whether all the fixtures of the fixture are on the same vertical plane, if not, adjust the blocking screw on the connection block to make the fixture on the same vertical plane.

8. Semi-automatically fine-tune the gripping position, after the adjustment is OK, save the parameters.

9. Then set the posture position of the manipulator in turn, the open position on the way, the open position of the product, etc.

10. Enter the manipulator timer module and make preliminary settings for each action time. And preliminarily set the ejection delay (2s) and back delay (5s) of the ejector pin of the injection molding machine.

11. Fully automatic operation of injection molding machine and manipulator.

12. In the first fully automatic state, because the robot can have a better cooperation with the injection molding machine, please carefully observe the operation of the two equipment in the fully automatic state, and then fine-tune the timing of the robot and the injection molding machine. Item time (thimble ejection delay, thimble retreat delay, intermediate cycle time, etc.) so that the manipulator can react quickly and stably.

13. After the adjustment is completed, fully automatic production is carried out. You can leave after observing 20 molds or more than half an hour and there is no fault alarm.

2. Precautions for the use of the injection molding machine manipulator

1. When the external power supply is abnormal, the control system will malfunction. In order to make all the systems work safely, it is necessary to install a safety circuit outside the control system.

2. It is necessary to understand the contents of this manual before installation, wiring, operation and protection. It is also necessary to be familiar with mechanical and electronic knowledge and all relevant safety precautions when using it.

3. Please install it on metal and other flame-retardant materials and keep away from combustible materials.

4. Grounding is necessary when using.

5. The wiring work must be carried out by a professional electrician.

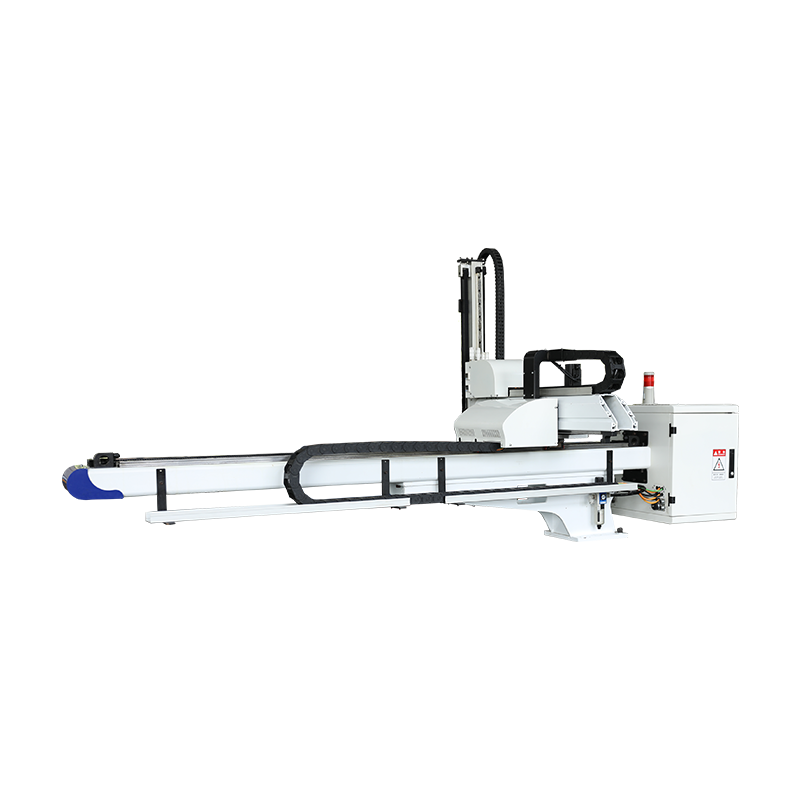

robot arm for injection molding machine