Until now, robots had only been capable of performing narrowly defined tasks. They could pick up a single type of object from a specific location, and at a certain orientation. But now, thanks to advancements in robotics, robots can see, analyze, and transmit valuable data to management systems. This improves machine uptime and reduces maintenance costs. Robots can also enhance worker safety. They can now operate in potentially hazardous environments and perform tasks posing a high risk of injury.

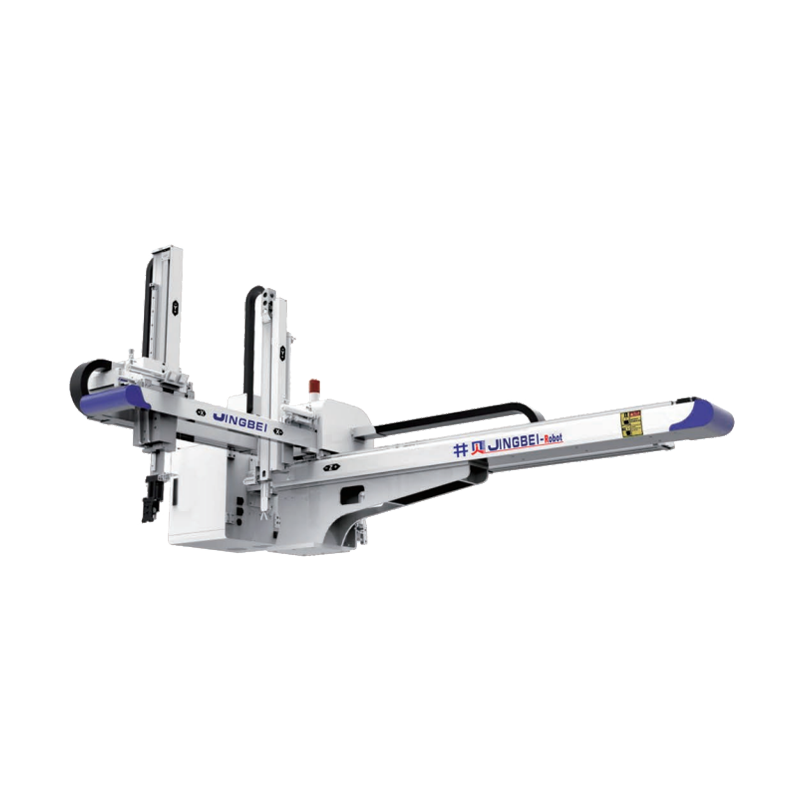

The Phaser series traverse robots feature a three-axis motor drive for a high degree of precision, and are ideal for low-overhead applications. Its pneumatic and electric motors offer fast part handling and a wide range of control options. It can also handle parts up to fifty pounds. It has a maximum climbing slope of 25 degrees and can traverse obstacles up to 400 mm.

The versatility of the Traverse Robot Arm is further enhanced by its hydraulic actuation system. This makes building high-DOF machines easier. It also enables multilegged robots to move more easily. Its versatility makes it ideal for research, and in some fields it could be used to improve human healthcare. With the versatility of the Traverse Robot Arm, the possibilities are endless. Its flexibility is a major advantage for the next generation of robotic arms.

The Lauron-V robot can traverse large obstacles, maintain balance on slopes, and manipulate objects using its front legs. Its behavior-based control system lets it navigate even the most unstructured environments. Its versatility is a major advantage to many companies looking to automate tasks. It has the potential to improve productivity in many fields and environments. It can be used for simple jobs to complex tasks, and it can operate safely in a range of environments.