4: Pneumatic system

Including the multi-axis servo drive, as long as there is a wrist rotation and vacuum gripping action, almost all robot arms will have pneumatic functions. Pay close attention to the suction cup of the filter regulator valve unit. The accumulation of water in it indicates that the humidity of the compressed air source passing through the system is too high. The presence of a small amount of water vapor may be transmitted to the pneumatic valve and actuator, causing oxidation and internal pollution, which may eventually cause the pressure regulating valve to stick or the actuator to stick intermittently or fail.

If the suction cup is equipped with an automatic dehumidification system, contamination or discoloration on the suction cup also indicates that moisture is increasing before removal. If water accumulates in the suction cup, even if the time is short, it can enter the system, causing the above problems. If you notice any physical damage to the pneumatic hose, there may be a leak in the system.

If the pneumatic circuit is filled with air at normal operating pressure and a leak occurs somewhere in the circuit, then you should be more likely to notice a clear hissing sound, which will help you determine the location of the leak.

5: Check molding equipment

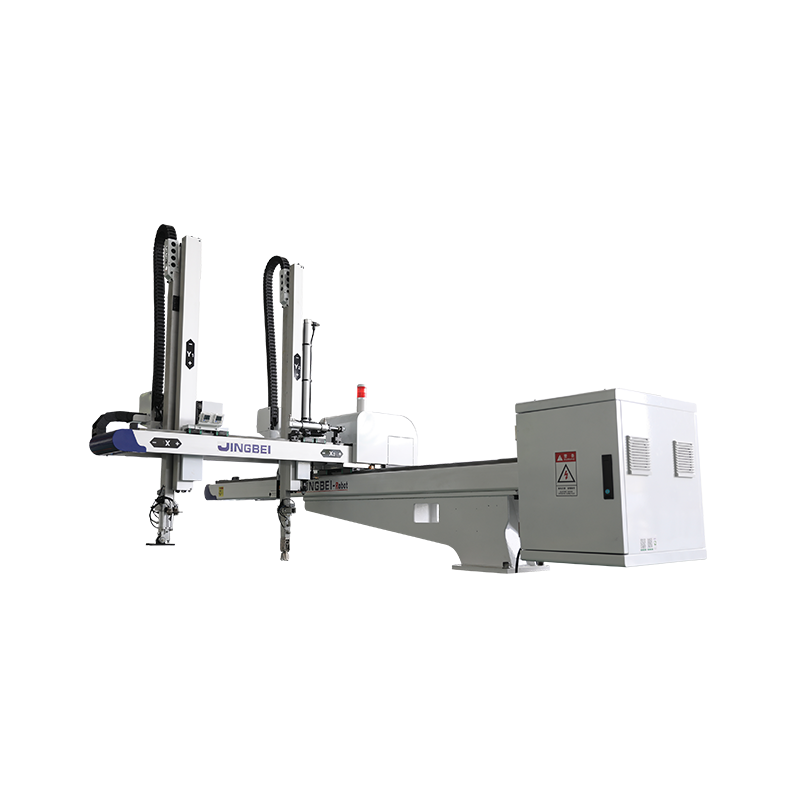

The robot arm with standard configuration is usually installed on the template of the molding equipment. When the equipment is running quickly, vibration from the molding equipment may be transmitted to the robot and may cause damage. Simply observe the operation of the molding equipment to ensure that the mold movement is adjusted to a reasonable state, reduce the number of shaking or vibration, which could extend the life of the robot arm. In high-speed operation, the vibration frequency may be very high, it is best to install the robot arm on a support structure independent of the molding equipment.

6: Pay attention to wiring wear

When inspecting the surface of the robot arm, if black particles or powder are found, it indicates that the circuit wiring of the robot arm has signs of wear. However, even if you can’t find these wear signals, look carefully at all power, transformer, or encoder cables, both the inside and outside of the wiring path, because during the production cycle, the wiring of the robot is continuously rubbed or connected to the cable guide. The wiring will eventually wear out and fail. Ensure the safety of wiring cable ties and the proper installation of cables.

7: Check the lubrication

Robot arm uses spring-loaded lubricating rods. Unless there is evidence that the rails are not sufficiently lubricated, they only need to be replaced once a year. Equipped with an automatic lubrication system, it can continuously lubricate along the movement of the robot arm. However, if there are some surfaces on which the robot arm cannot move normally, then manually lubricate these areas, or implement periodic program-controlled actions for the lubrication of automated systems. If you notice rust, corrosion or wear on any moving surface, or it is just too dry, it means that they are not well lubricated. Always refer to the manual of the robot for proper lubrication of metal parts. Assembly beam-The traditional gear system is automatically lubricated by a lubricant storage unit, but it needs to be replaced every year.

8: Vacuum gripping circuit

The vacuum should be formed almost instantaneously, and the appropriate controller input should be equivalent to grabbing the product. If you find that the vacuum is turned on, then the input light source appears, and the delay time exceeds 2 seconds, then it indicates that there is a leak in the vacuum line, a defect, or the switching device is not adjusted properly. It can be easily tested through the plug-in main control panel.

If the robot is equipped with a digital vacuum switching unit, you can quickly and automatically fine-tune the minimum threshold of vacuum required to grab the product. We believe that this process can be completed when the robot is running in automatic operation mode. The setting parameters of each production cycle are saved in the memory, which can save time in the next production change. The digital vacuum switching device has two other advantages: the electronic filter for grasping the threshold signal compensates for the vibration of the product on the vacuum suction cup during rapid movement. The product release threshold is different from the grab threshold and can be programmed to ensure proper release under rapid production cycle conditions.