For a traditional manufacturing enterprise, changing our production mode by using the injection molding machine manipulator is the only way to reduce the dependence of enterprises on employment, cut production costs and realize sustainable development. With the increase of the frequency of use, the output of industrial production can be raised immediately. The robot arm for the injection molding machine is widely used in electronics, textile machinery, villatic manage machines and other industries, which greatly improves the production efficiency. Many industries have further developed the production efficiency and quality after reorganizing and using the robot arm.

Robot arms have a great influence on modern production industry. They not only drive a new round development of traditional industries, but also have market competitiveness no less than that of modern sunrise industries.

The application of plastic molding automation is very common, and the manipulator mainly has the following uses in the application process:

1. The robot arm takes out the in-mold products, replacing the original semi-automatic production to fully automated production.

2. The robot arm takes the products out of the mold and embeds the products in the mold (labeling, embedding metal, two-shot injection molding, etc.).

3. Automatic packaging and warehousing after the manipulator takes out the product.

4. Automatic feeding systems for molding raw materials and waste recovery systems.

5. Production control systems of the whole plant.

The injection molding machine manipulator uses the the modern production technology, and the modern management mode has greatly improved the vitality and market competitiveness of enterprises. Thus, many enterprises have dozens of product varieties now (there used to be less than a dozen), and the number of high-quality products has been greatly increased compared with the previous ones. The key influence is to enhance the market competitiveness and viability of enterprises.

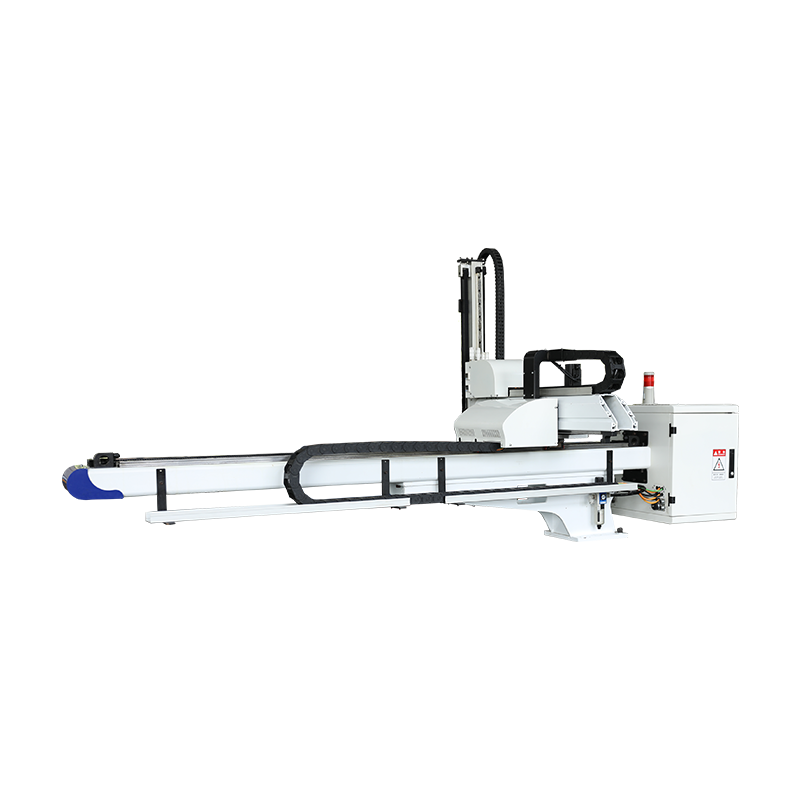

single axis servo robot arm