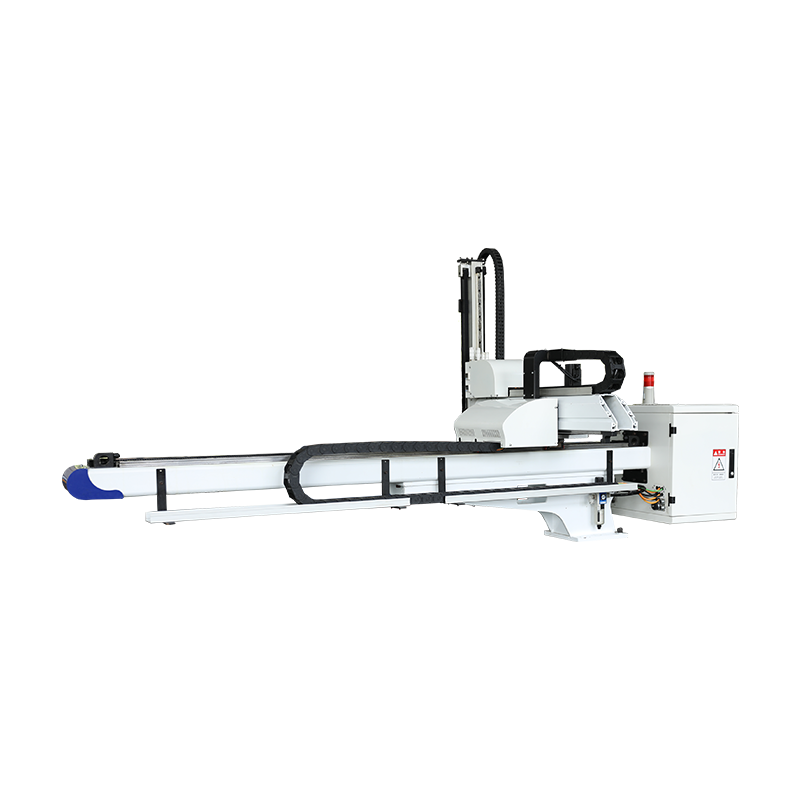

1. Mature product of "machine substitution": The handling manipulator has undergone 5 years of R&D and application tests, and the product has been continuously improved and technologically innovated, and it is mature and reliable.

2. Optimal cost performance: achieve large-scale mass production, optimize cost control, and have the most competitive product prices in the market

3. Quick and personalized customization: The professional technical team can quickly customize automation solutions according to different product and process requirements of users.

4. Quick adjustment: The manipulator adopts the manipulator numerical control system (non-PLC mode) independently developed and has independent intellectual property rights, which is easy to learn and use.

5. Strong versatility: The universal design of the handling manipulator not only meets the automatic production of "small variety and large batch" workpieces, but also applies to the application requirements of "multiple varieties and small batches".

6. Super long service life: The handling manipulator adopts the core hardware accessories of the world's first-line brands, and the service life of the whole machine is more than 8 years.

7. Ultra-low maintenance cost: The handling manipulator is highly packaged and integrated, with few failure points, no professional maintenance, and extremely low maintenance cost. The fully automatic handling manipulator can be customized according to customers, for large flanges in casting, forging, metallurgy, and machining industries , gears, turning workpieces, discs, cylinder workpieces, rollers, engine casings, reducers and other workpieces, in turning, CNC machining centers, automatic detection lines, large gantry milling machines, gantry grinders and other processing measurement methods can be replaced. Manually realize the automatic handling of the workpiece, send it to the designated position, realize automatic flipping, and move it away from the machining center after processing or measurement to realize automatic loading and unloading. The fully automatic handling manipulator can complete heavy objects grabbing, handling and transfer actions, and is an ideal handling tool for material handling.